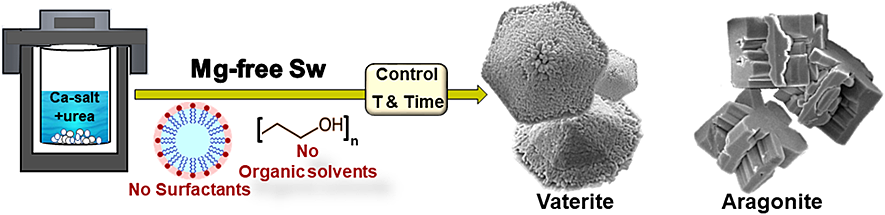

CO2 storage and utilization through mineral carbonation

Applications

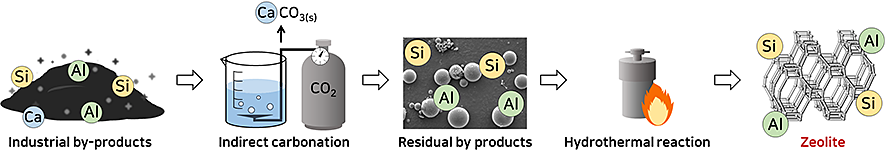

Zeolite synthesis using industrial by-products

Applications

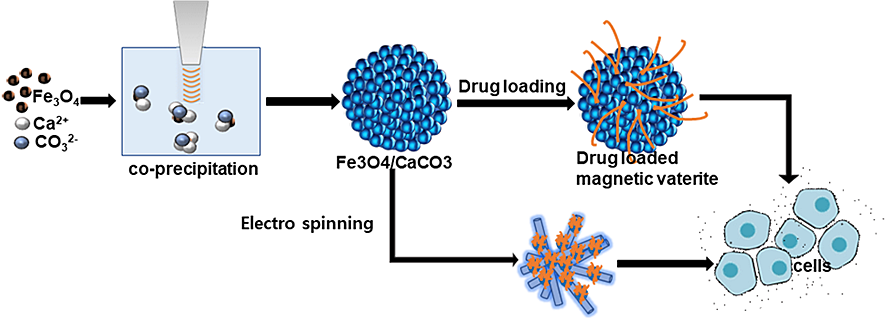

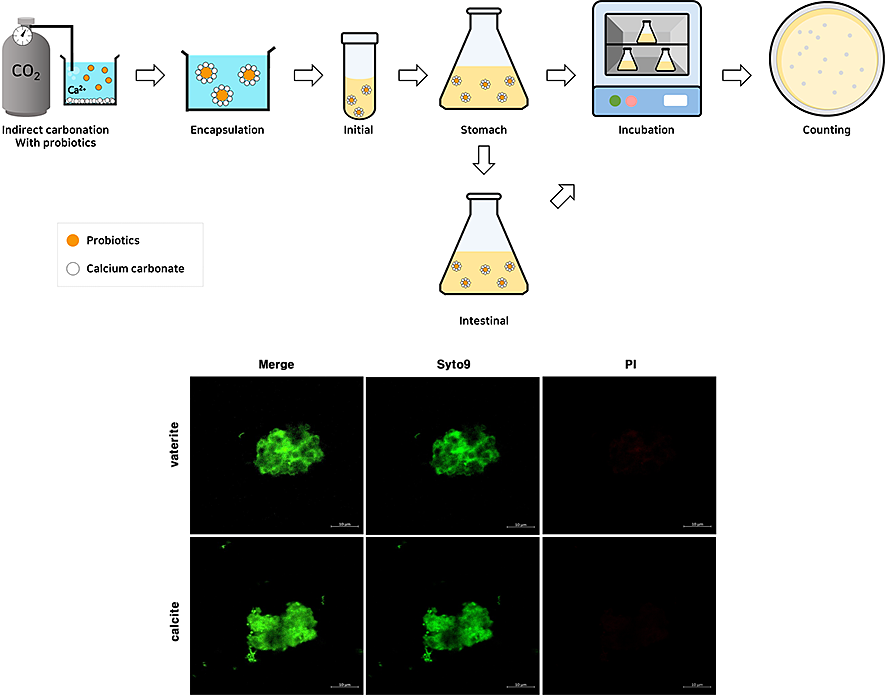

Encapsulation of probiotics with calcium carbonate

Applications

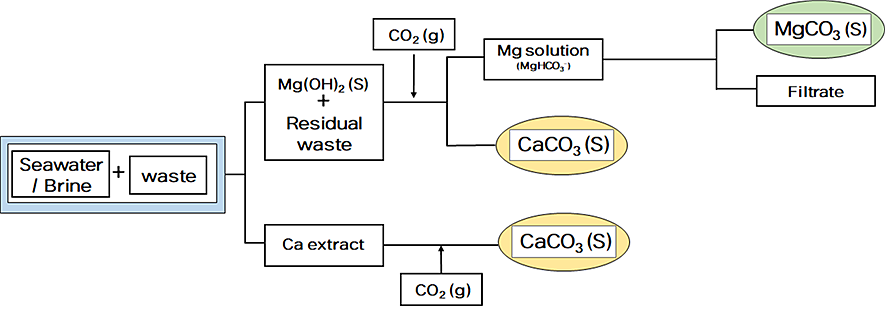

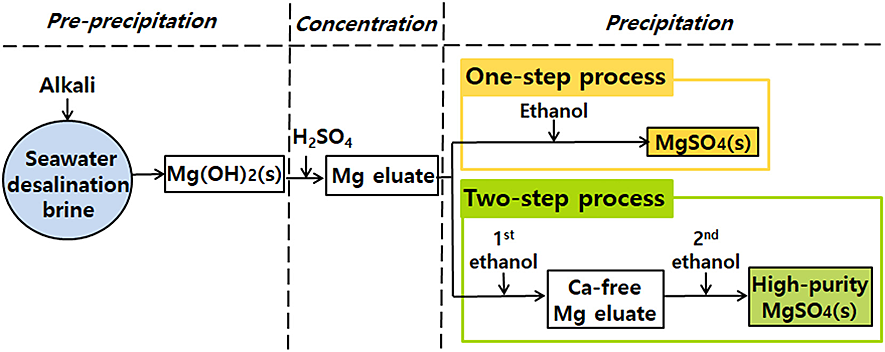

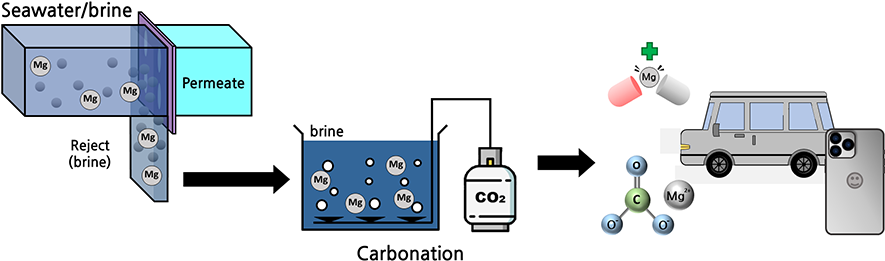

Magnesium recovery from seawater/brine

Applications